The Rise and Fall of the World’s Most Successful Joint Venture

For more than a quarter century, the fortunes of the United States and China were fused in a uniquely monumental joint venture.

Americans treated China like the mother of all outlet stores, purchasing staggering quantities of low-priced factory goods. Major brands exploited China as the ultimate means of cutting costs, manufacturing their products in a land where wages are low and unions are banned.

As Chinese industry filled American homes with electronics and furniture, factory jobs lifted hundreds of millions of Chinese from poverty. China’s leaders used the proceeds of the export juggernaut to buy trillions of dollars of U.S. government bonds, keeping America’s borrowing costs low and allowing its spending bonanza to continue.

Here were two countries separated by the Pacific Ocean, one shaped by freewheeling capitalism, the other ruled by an authoritarian Communist Party, yet conjoined in an enterprise so consequential that the economic historian Niall Ferguson coined a term: Chimerica, shorthand for their “symbiotic economic relationship.”

No one uses words like symbiotic today. In Washington, two political parties that agree on almost nothing are united in their depictions of China as a geopolitical rival and a mortal threat to middle-class security. In Beijing, leaders accuse the United States of plotting to deny China’s rightful place as a superpower. As each country seeks to diminish its dependence on the other, businesses worldwide are adapting their supply chains.

The production line at an electric vehicle factory in Hangzhou Bay, China. Chinese companies are harnessing the know-how gleaned from joint ventures with foreign automakers.Credit…Lorenz Huber for The New York Times

Chimerica has yielded to a trade war, with both sides extending steep tariffs and curbs on critical exports — from advanced technology to minerals used to make electric vehicles.

American companies are shifting factory production away from China to less politically risky venues. Chinese businesses are focused on trade with allies and neighbors, while seeking domestic suppliers for technology they are barred from buying from American companies.

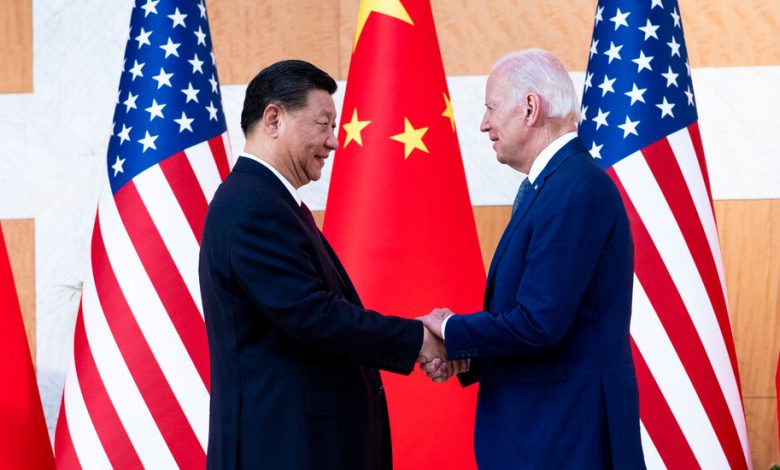

Decades of American rhetoric that celebrated commerce as a wellspring of democratization in China have given way to resignation that the country’s current leadership — under President Xi Jinping — is intent on crushing dissent at home and projecting military might abroad.

For Chinese leaders, the once-prevailing faith that economic integration would undergird peaceful relations has been relinquished to a muscular form of nationalism that is challenging a global order still dominated by the United States.

“In a perfect political world, these are two countries that are made in heaven, exactly because they are complementary,” said Yasheng Huang, an economist at the Massachusetts Institute of Technology Sloan School of Management. “Essentially, these two countries kind of got married without knowing one another’s religions.”

But divorce is not a practical option. The United States and China — the world’s two largest economies — are intertwined. Chinese manufacturing has evolved from basic areas like footwear and apparel into advanced industries, including those central to efforts to limit the ravages of climate change. The United States remains the paramount consumer marketplace. Even as geopolitical tensions fray their ties, these two countries still depend on each other, their respective roles not easily replaced.

Apple makes most of its iPhones in China, even as it has been shifting some production to India. A Chinese brand, CATL, is the world’s largest maker of electric car batteries, and Chinese companies dominate the refining of critical minerals like nickel used in such products. Chinese businesses make up more than three-fourths of the global supply chain for